3D printing

MIDDLE FINGER JOINT AND SOCKET PRESSFIT

FIRST ROUND:

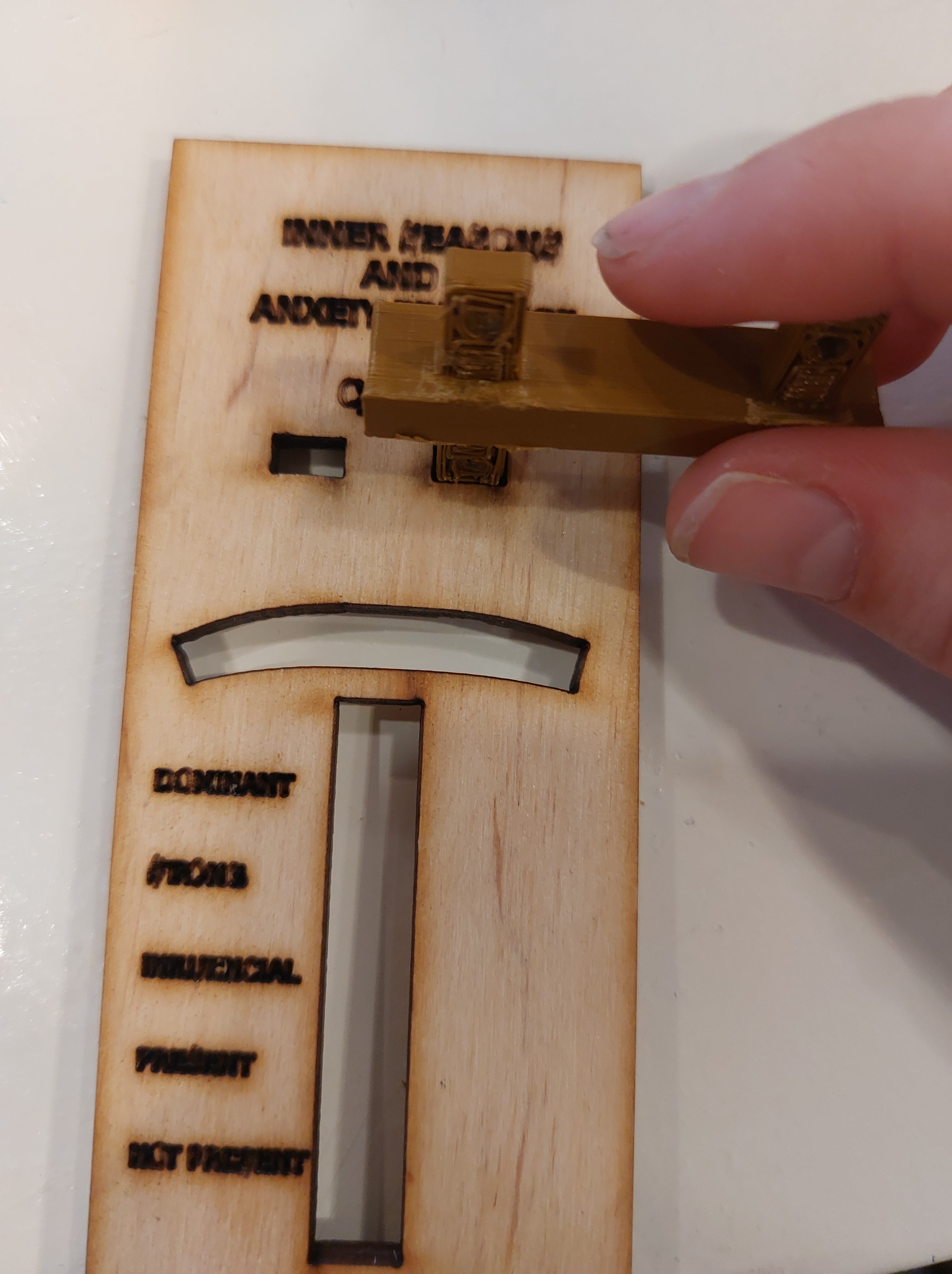

As I mentioned before, the middle connection point between the two base faces that keeps all the components together, isn’t stable enough. I want to try 3D printing this, so that the structure is more dense and not made of multiple pieces. My first test shows below:

I used the same design in Fusion of the middle connection piece, and made the teeth 6mm longer in height. You can see, however, that the faces of the teeth are too wide and long. This is probably because there is little to no play in the structure of filament compared to the wood. There is also no Kerf from a laser that eats material. I think if I add a negative offset of 1mm, it will work better.

In the image above you can clearly see that the position of the teeth is also completely off. I forgot that I had changed the positions in Lightburn, for a reason I cannot recall. I will have to measure the physical bases to make the connection piece allign, or recut the bases.

SECOND ROUND:

DESIGN

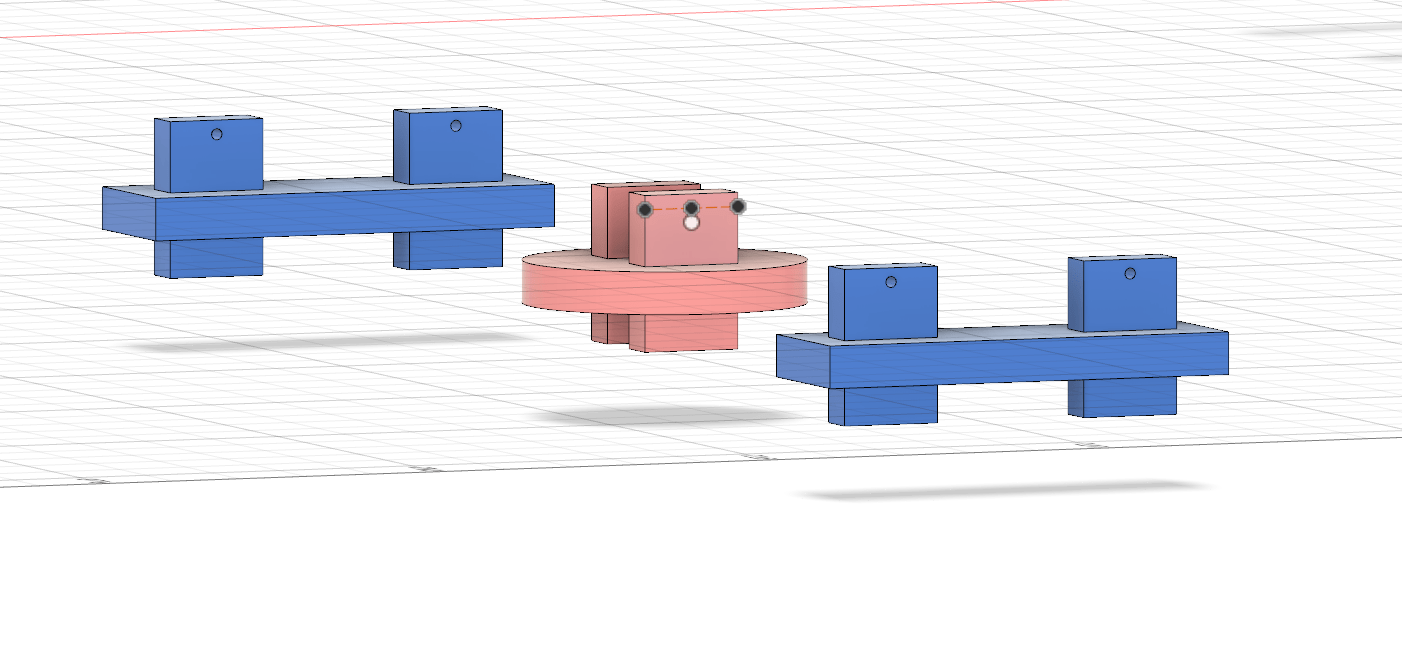

- For this first print, I wanted to use no offset, just so I could see how strong and well the design would come out. I can then compare it to the lasercut pieces and guage how much play it will need to fit well.

in fusion 360

in fusion 360

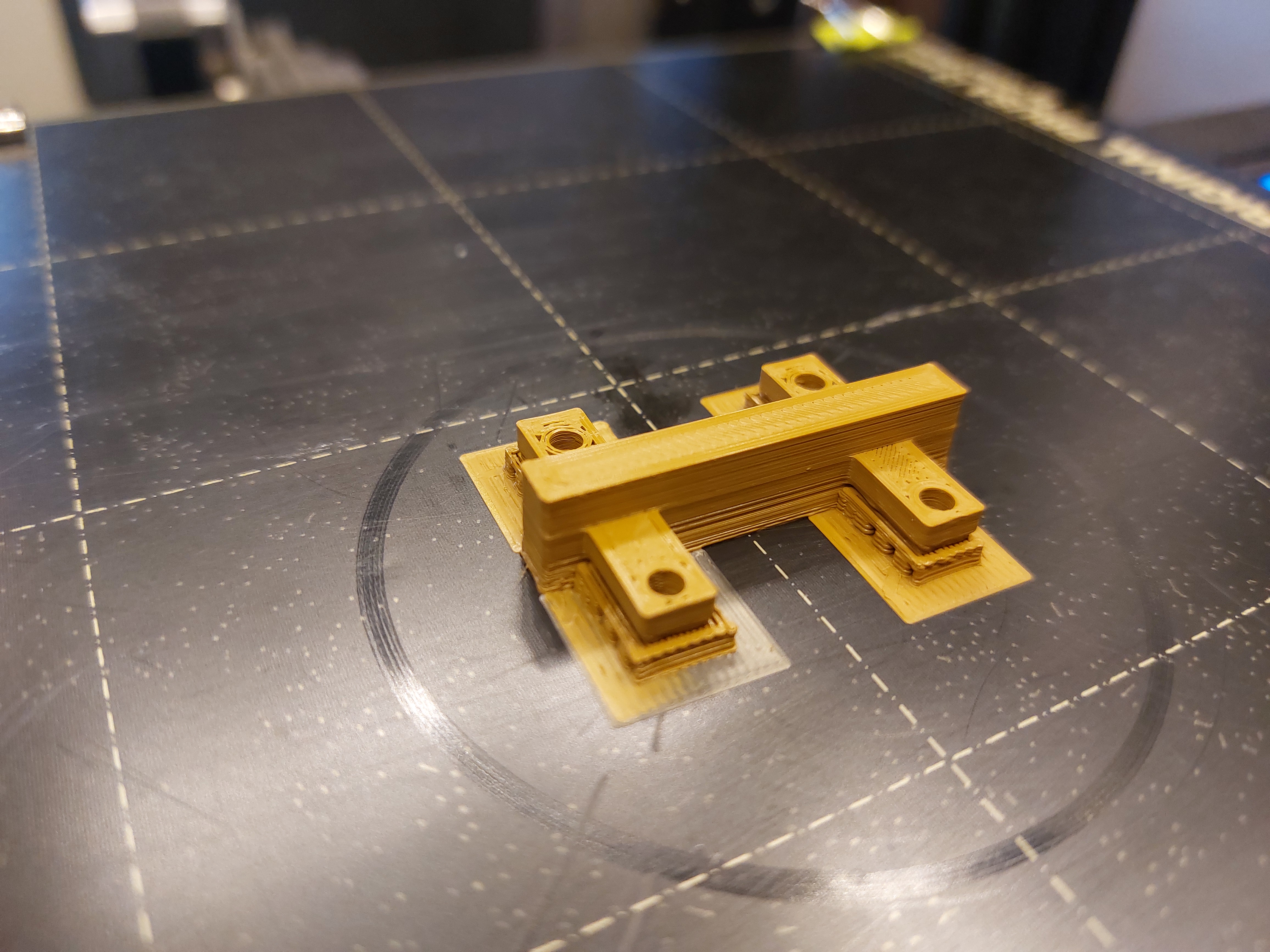

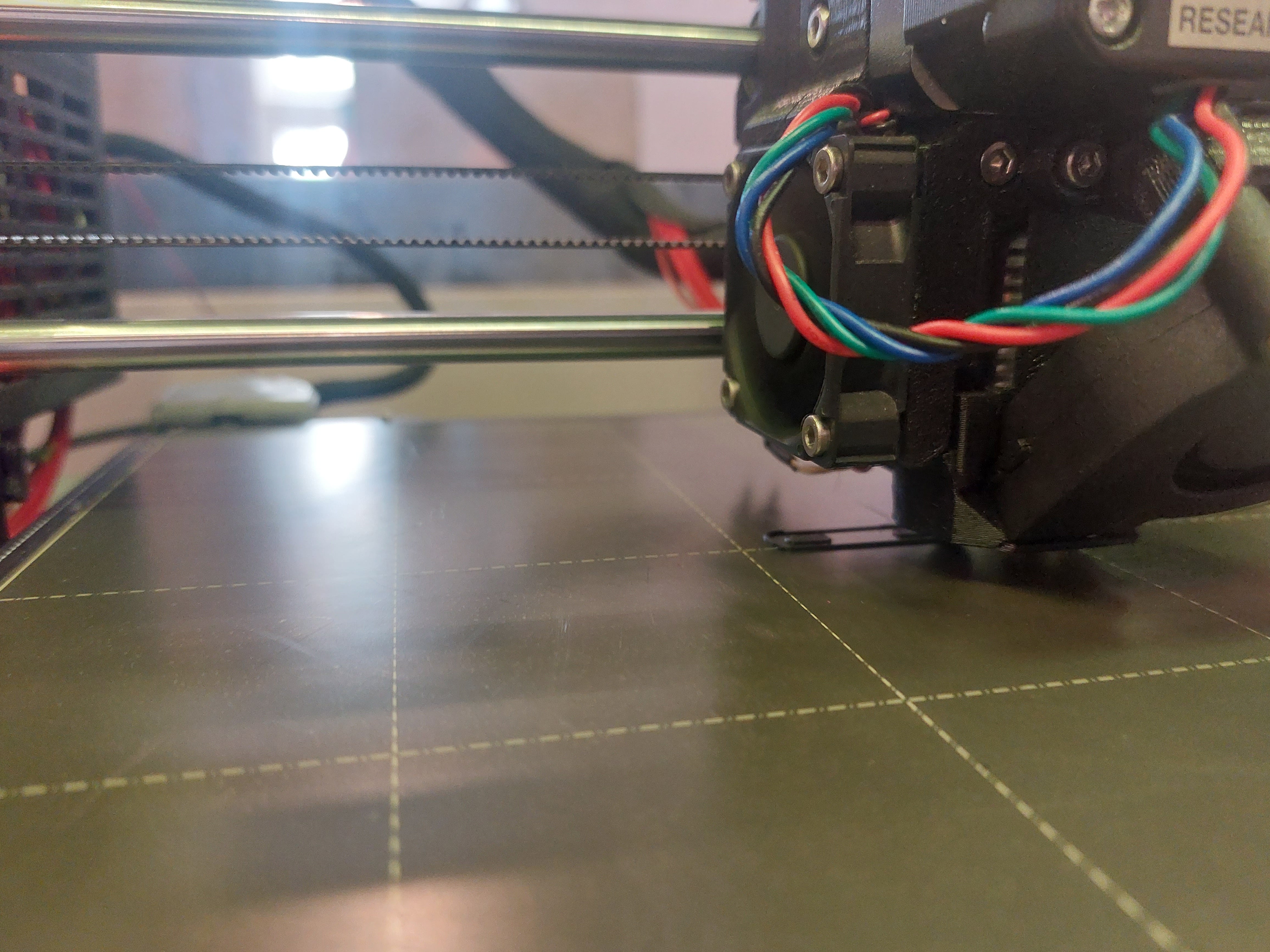

MAKE

Around 40% way through the job, the print would start warping and let go of the bed. The first time I cleaned the bed better, no difference. I then made the bed warmer (65 degrees), no difference. I went back to Prusa slicer and added support with the paint-on support tool on the overhang (automatically generated support showed nothing), because that is about the point where it would let go of the bed. I also went from QUALITY 0.15mm to DETAIL 0.10mm in print settings.

mid joint component

mid joint component

tests that came out warped

tests that came out warped

printing well

printing well

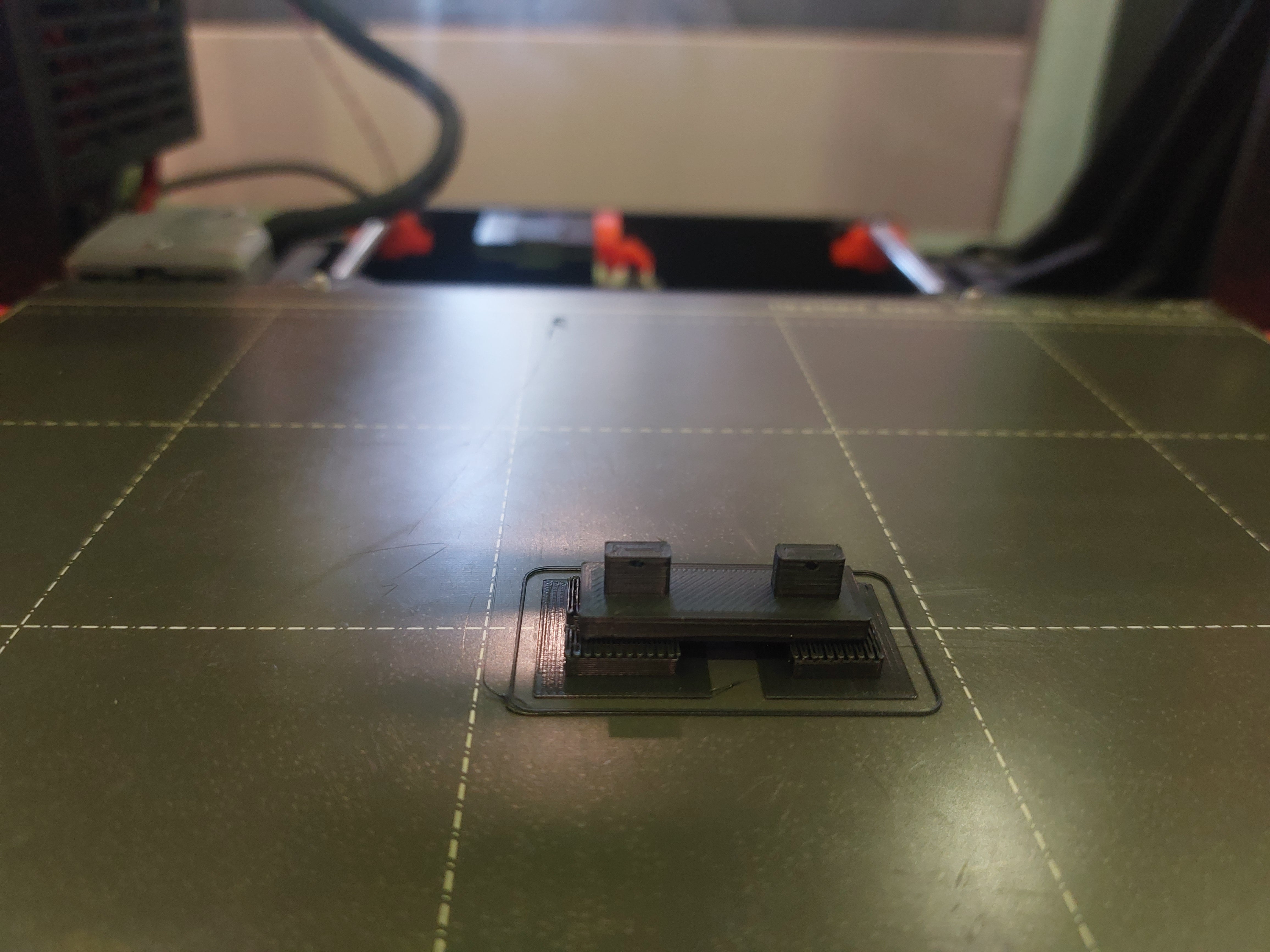

print done

print done

image of iteration 2 3d print being slightly too tight

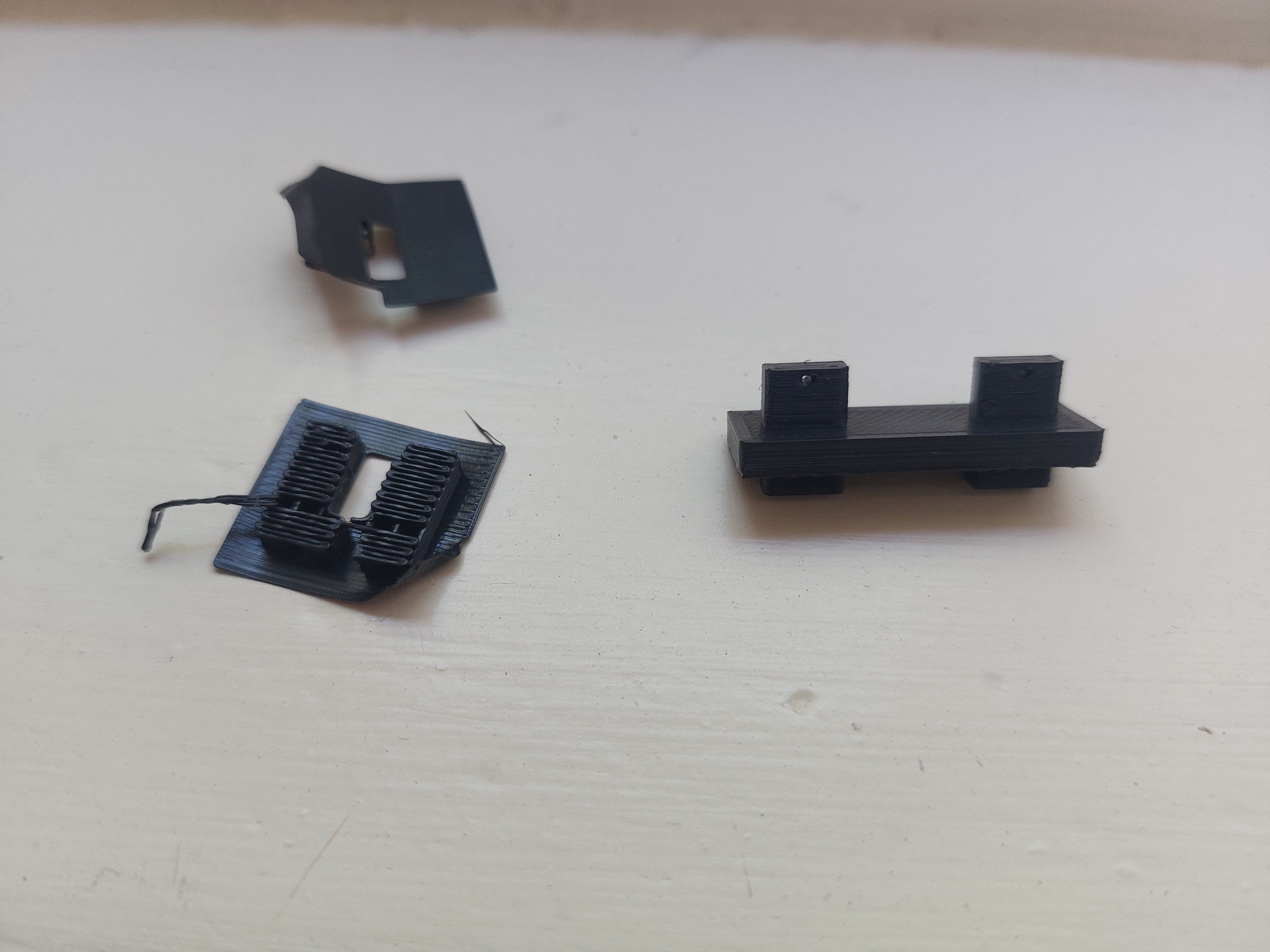

print 2

print 2

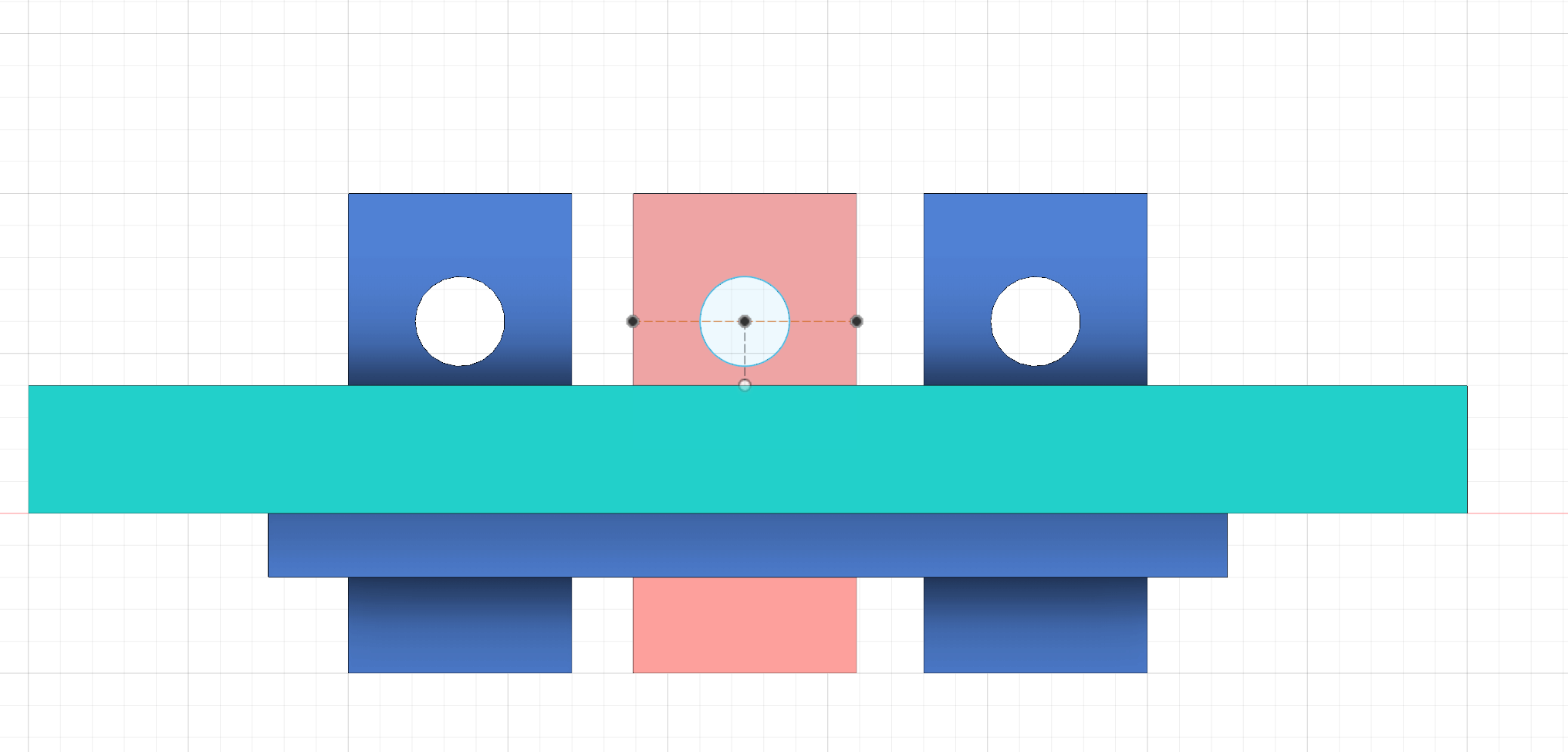

adapted parametrically

adapted parametrically

print 3

print 3

- The hole is still a little too tight, will give it slight more play (1mm in diameter). I will wait for this until I have my lasercut components to see if the pressfit fingers need adapting as well.