GEAR PRODUCTION

I want to make a bunch of different gears that I can control through stepper motors.

Laser cutting gears

3D printing spiral gears

https://www.thingiverse.com/thing:29596/comments

- gear pairs

print 1

print 1

Filament: MagicPLA Metallic Emerald Diameter: 1,75mm 1000G

Nozzle temperature : 215-235 degrees

Bed temperature : 50-70 degrees

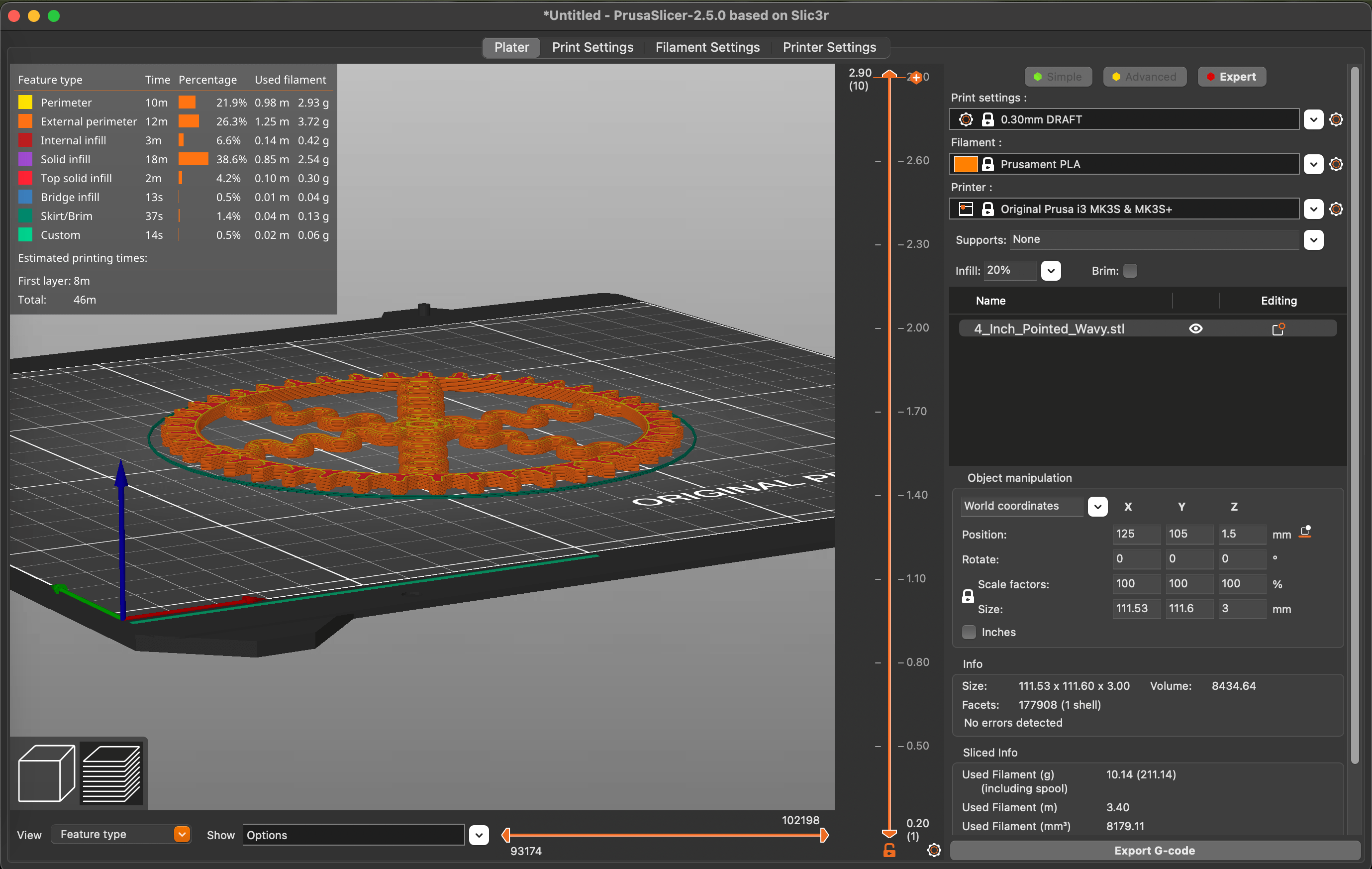

Print settings : 0.30mm DRAFT

Layer height: 0.3mm

Size: 111.53 x 111.6 x 3 mm

Supports: None

(image of print 2)

(image of print 2)

Michelle showed me a Twist Lock Trick Box after I showed her the second gear print: https://www.thingiverse.com/thing:4927585

- this would be a cool mechanism for when I want to make replacable components to the larger machine.

Gear pairs March 2023

1

I want to make this mechanism: http://507movements.com/mm_068.html to represent the dynamic between one day and one menstrual cycle. My average cycle is 29 days so I will be using that.

I want them to sit on my stepper motor, so that I don’t need to make a component to attach them together.

Step 1: Important Dimensions

Stepper motor JK42HS40-1704-83AF cylinder pin : 4.95mm diameter

Stepper motor 28BYJ-48 pin: 2.88mm x 4.87mm

Gear B # of teeth: 29 Gear A # of teeth: 1

Step 2: Design in Fusion

NOTES: Backlash:

- the defined clearance between a gear and its mating gear

- with 3d prints, you need built-in tolerances .15mm works well with the size in the tutorial (this will end up being .3mm because we will give the same tolerance to the second gear)

- does depend on print setting

Root fillet radius:

- the higher the value, the stronger the gear teeth, but can’t be larger than 1.1mm

- you want to avoid an undercut shape of the teeth or the gear teeth will not roll smoothly off eachother

Hole Diameter:

- You can apply the center hole here, but you can also apply it later so you have more flexibility

GEAR B:

pressure angle: 20 degrees module: 12.7 number of teeth: 29 backlash: .15 root fillet radius: 6.588 gear thickness: 5 hole diameter: 4.95 pitch diameter: 368.3

GEAR A:

pressure angle: 20 degrees module: 12.7 number of teeth: 29 backlash: .15 root fillet radius: 3.25 gear thickness: 5 hole diameter: 4.95 pitch diameter: 368.3

Gear to motor connection piece

bed of gear: 30mm diameter bed of connection piece: 20mm diameter

Stepper motor 28BYJ-48 pin: 2.88mm x 4.87mm

In Prusa Slicer:

- Creality Ender 3

- Infill 20%

- No brim

- No support

- DRAFT

(image of printed object)

NOTE: the hole was too small for the step motor pin- make it slightly bigger on both width and length

RESOURCES

https://inkscape.org/~abe.karnik/★render-gear-pair https://inkscape.gitlab.io/extensions/documentation/authors/update1.0.html